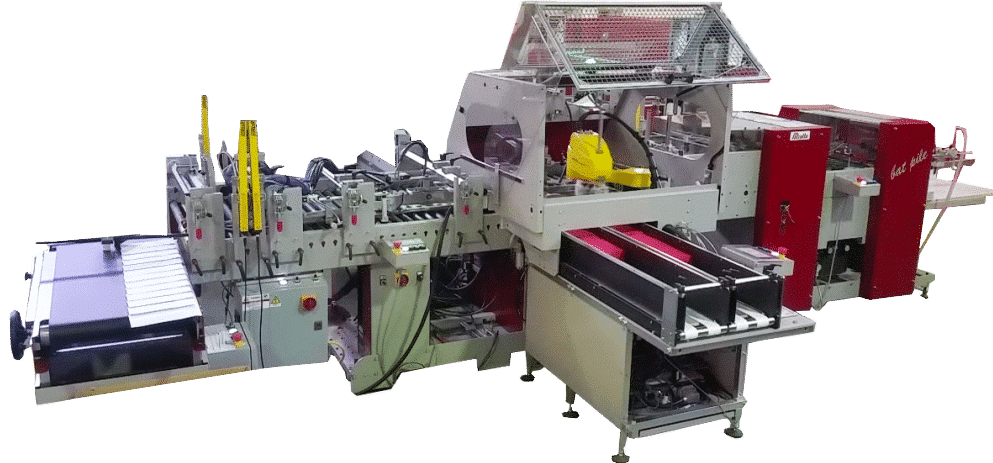

Machine for making the cutlery bag with folded napkin inside.

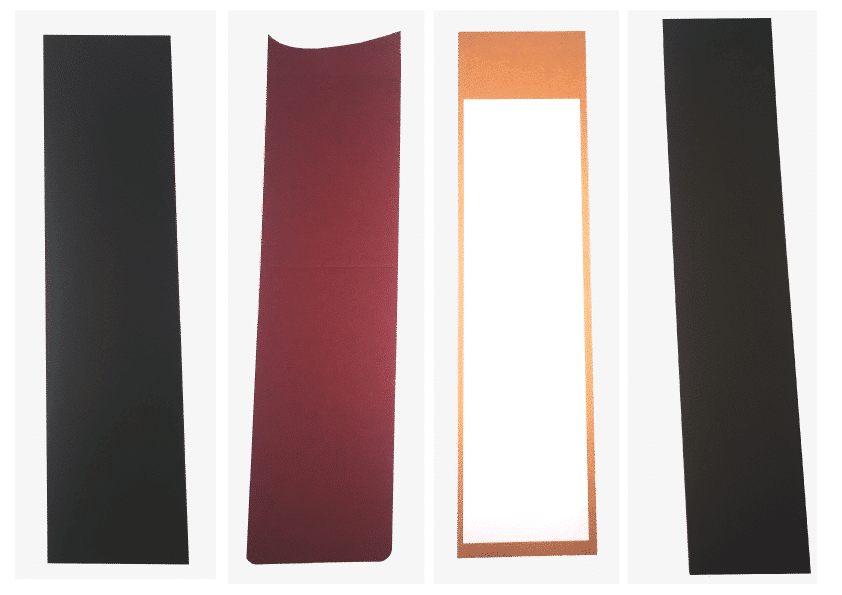

Metro Napkins is the automatic line developed and manufactured in cooperation with industry manufacturers, that allows the handling by a single operator of the full process in a single step with different types of materials and production speed.