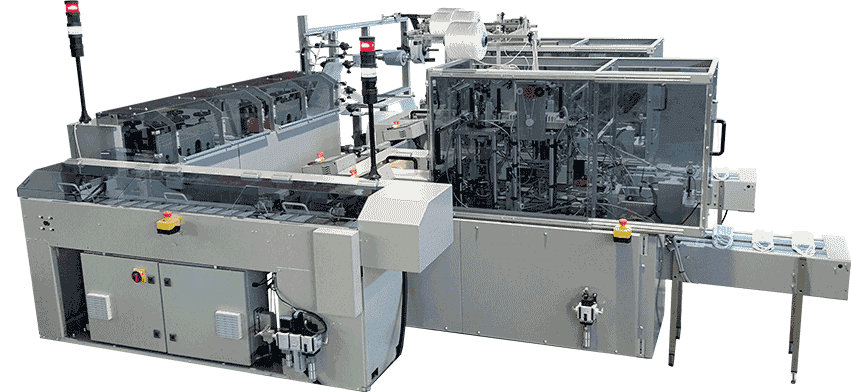

Machine for the production of masks in non-woven material (TNT).

Fully automatic with double delivery line, equipped with all safety devices according to the CE standard.

SKY

AUTOMATIC MASKS MAKING MACHINE

S.

solution

n.

Need

Many companies have been looking to diversify their production in reaction to the COVID 19 Pandemic and the exponential demand of surgical masks. The machines utilized for the purpose have to be highly performing, reliable and compliant to the CE standards to allow producers to respond on time to their customers.

Petratto SKY is the result of R&D activity to provide a productive, reliable and safe machine. All the mechanical parts are made in Italy, the electric components are made in Europe, the software has been developed and it is owned by Petratto and the machine is assembled in the factory in Pianezza (Italy)

A key priority has been security. PROTECTIONS have been conceived to prevent access to dangerous areas of the machine. All the moving parts of the machines which could constitute a danger are protected by fixed or movable guards locked to prevent accidental contact and avoid damage.

.

General description:

SPEED APPROX.: 6.000 C/H (100 PC/MIN)

TOTAL FOOTPRINT APPROX.: 6 X 3.5 MT.

TOTAL POWER APPROX.: KW 17

COSTRUCTION OF MECHANICAL PARTS: ITALY

ASSEMBLY AND TESTING: PETRATTO FACTORY IN TURIN

ELECTRIC COMPONENTS: EUROPE

SOFTWARE DEVELOPED AND OWNED BY PETRATTO

CE CERTIFICATION – MANUALS IN ENGLISH

- Machine for the feeding of the coils (1)

- Machine for the coupling, ultrasonic welding, of the various layers and cutting the mask to size (2)

- 90° connecting line (3)

- Two machines fot the welding of the side straps (ear strap) (4/5)

- Protections that prevent access during operation according tc CE standard.

INTERNAL LAYER

Filtering layer

external layer

Type of materials: Melt blown fabric

Width: 17.5 cm Gr. 20-25

Type of materials: Melt blown fabric

Width: 17.5 cm Gr. 20-25

Type of materials: Melt blown fabric

Width: 19.5 cm Gr. 20-25

Nose shape support

Rounded ear strap

Dimension of coils usable

Width: 3 mm Thickness: 0.7 mm Length: 95 mm

Diameter: 2.5 mm Length: 20 cm

Width: 180 / 185 / 190 / 195 mm

Internal diameter: 35-85 mm

External diameter: 600-800 mm

Coil feeding group

4 coil holder for layered materials.

1 coil holder for nose shape support.

Coupling - welding -cutting group

Coupling of material layers.

Inserting the nose shape support, with the possibility of adjusting the length of the insert.

Ultrasonic welding, via sonotrodes, longitudinal edges (long side of the mask).

Mechanical folding (concertina type).

Ultrasonic welding, via sonotrodes, transversal edges ( short side of the mask).

Cut to size of the mask.

Deposit on sectoral channel for deflect 90 ° the single mask.

Sorting group with 3 outputs

Motorized “channel” with sectors.

2 alternating pneumatic pushers for sending the masks to the supply channels for the next step.

3rd exit for emergency (if one machine for ear strap is stopped, the other one continues the operation).

This Solution allows a compact footprint of the machine.

N°2 LINE TO CUT / FORM / WELD THE EAR STRAP

Channel / belt reception of single masks.

Ear strap feeding.

Legth cutting with preparation and insertion.

Ultrasonic welding, using sonotrodes (it is used to melt the strap on the inside of both ends of the mask body).

Single mask collection on belt.